|

A degasser that makes your choice easier |

|

|

Well Control Model 5200 |

|

|

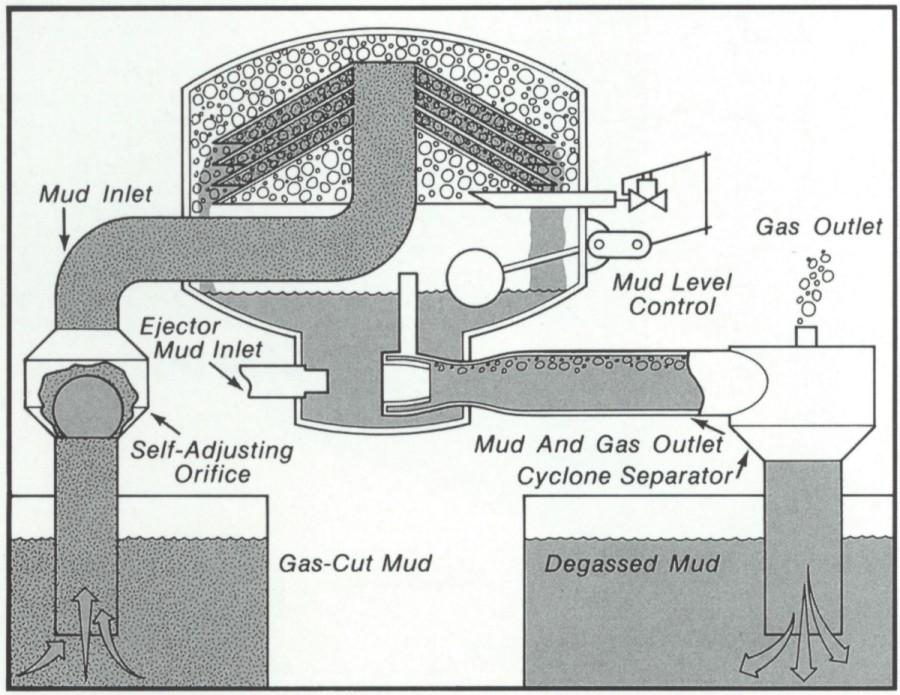

If you're looking for simplicity and sturdy construction

in a degasser, make Well Control your Choice. Our Model 5200 is

constructed with no need for a mechanical vaccum

pump. It uses a dual ejector venturi, powered

with mud from the rig pumps, to remove mud and gas simultaneously. The

model 5200 requires no moving parts for operation, a design advantage which

insures dependable performance at all times and eliminates costly down time

due to vaccum pump failure |

|

|

Operation: The Well Control Model 5200 utilizes a vaccum, both for treating gas cut-mud and for drawing it into the treater vessel and the pipe, eliminating the need for expensive vaccum pumps or blowers. The dual venturi produces enough vaccum to handle and degas all weights of mud at high volumes. Drilling mud is jetted through the dual venturi at 35 to 55 PSI, creating a low pressure area. THis low pressure area creates the vaccum which draws gas-cut drilling mud into the vessel, where it flows down in thin layers over the special baffles. THe baffles allow for maximum exposure of mud surface to the vaccum in the vessel. The vaccum causes the gas bubbles in the mud to break out and the gas is then removed through the dual venturi. The treated mud falls into the lower reservoir, where the dual venturi ejects mud and freed gas is vented a safe distance from the rig. |

|