|

SeaSpring® |

The owner of this vessel has made his SeaOtter pay off by converting his water storage tank to a fuel tank, increasing his fuel capacity / trip range by over 50%. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Sea Otter Series Fresh water from the Sea 125 to 1,500 GPD

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Buying the Sea Otter components only allows you to fit into tight spaces and reduces cost. Assembly is required, but we furnish the instructions and a typical list of materials and tools required.

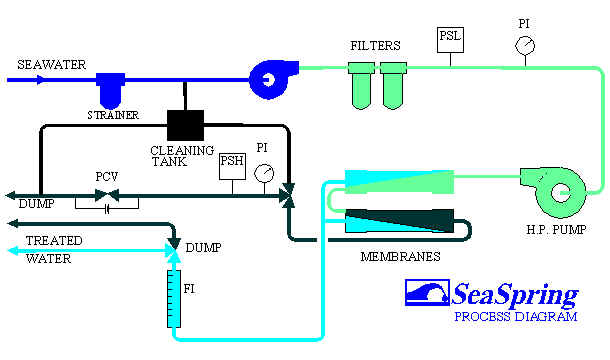

Clic on image to enlarge |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

SeaSpring Standard

Features The Sea

Otter Series SeaSpring TM desalination systems include all basic components

featured in the Dolphin and SeaLion series units,

designed for applications where water requirements are less demanding. Cartridge Sediment Filters Two cartridge sediment filters in series

are installed upstream of the membranes on every SeaSpringTM desalination systems. Both filters are designed to

use 1.0 to 25 micron elements. The primary filter will use either 10 or 20

micron elements, and the secondary filter will use 5.0, 2.0, or 1.0 micron

elements. The sediment filter housings are designed

to accept several different types of elements, and elements are easily

changed without special tools. High Pressure Pump High pressure pumps for Sea Otter Series

are close coupled CAT triplex plunger pumps. Standard material of

construction is Naval Aluminum Bronze (NAB) with stainless steel valves. Motor drivers for the high pressure pump

are 1 HP or 1.5 HP, TEFC, 115 V AC, single phase, 60 Hz or 220 V AC, 50 Hz

(specify voltage and frequency). Reverse Osmosis Membrane Membranes used in your SeaSpring TM desalination system are spiral wound, polyamide, thin film composite type manufactured by Hydranautics,

Inc., high capacity membranes that will remove 99.2% of dissolved solids. The

Sea Otter units will provide drinking water at rated flow and quality

(less than 500 PPM total dissolved solids (TDS)) from seawater sources (up to

45,000 PPM salinity and seawater temperatures from 50oF (10oC)

to 90oF (32oC). (Based on ASTM D1141 standard seawater

analysis.) Membrane Pressure Vessels Pressure vessels used in the Sea Otter series are available in FRP, 316 stainless steel, and Titanium. All are designed for operation up to 1,200 PSIG (80 BAR).

Monitoring System The Sea Otter SeaSpring TM desalination systems come standard with manual

valves and controls, of all corrosion resistant materials. Basic operator instructions are permanently

printed on the control console.

Optional automatic

controls include the following:

Structural Frame

Piping and Connections

System Maintenance Simplified

Optional Equipment Applications for seawater desalination are

not all the same, and your requirements are different from our other

customers. Your SeaSpringTM desalination system can be purchased with a wide

variety of options to make the best fit for your application and simplify

installation. Booster Pump

Media Filters Neutralizing Filters (Mineralizers) Anti-scale or Chlorine Chemical Stainless Steel Feed Pump

Stainless steel construction is offered

optionally for some of the CAT plunger pump (Consult factory). Instrumentation Options

Potable Water Disinfecting

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

SYSTEM OPERATION

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Other

Pages This Web Site SeaSpring is a trademark of Reetex, Inc. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||